Research Facilities

Centre for Optoelectronics have three cleanrooms (one class 1000 and two class 10,000) with microelectronics device processing equipments, facilities and state-of-art material growth facilities. The center's facilities, expertise and continuing research efforts would enhance the capability of the Centre to produce a wider range of Optoelectronics devices and Nano-photonics technology.

Equipment / Facilities Usage

Equipment Registration User Guides

Electron Beam Evaporation System (2 units) |

|

|

|

Super User: Musni

Edward E-beam evaporation system for Metal Deposition

Model: Edward Auto 306 Turbo

Substrate size: irregular to standard 8”dia wafer |

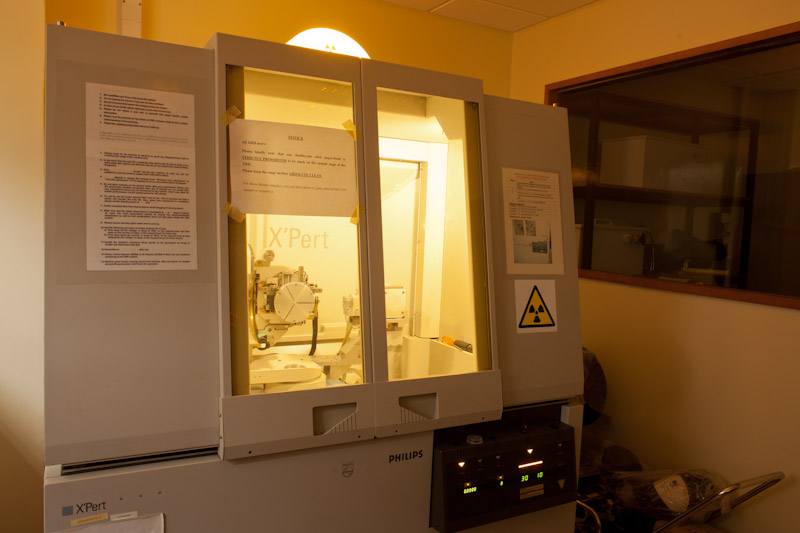

High Resolution Double Crystal X-Ray Diffractometer |

|

|

Super User: Rayson Tan (IMRE)

X-pert Pro-MRD, PW 3050/65 X-ray diffractometer

Model: X-pert Pro-MRD, PW 3050/65

X-Ray source: Cu

X-Ray Optics: (Incident beam optics) Ge(220) with mirror for 4 bounce high-resolution and high intensity, (Diffracted beam optics) Soller slits/collimators/monochromator. |

Inductively Coupled Plasma Etching System (ICP) |

|

|

Super User: Son Jae Sung

Plasma-Therm Inductively Coupled Plasma Etching System (ICP)

Model: SLR Series (SLR-770)

Substrate size: irregular to standard 8”dia wafer |

I-V Probe station |

|

Super User: Musni

Model: Micromanipulator-Model 6000 with Temperature-Variable Chuck

X-Y stage: moves 4"x4", chuck is for low contact resistance. The operating temperature can be varied from room temperature to 400*C.

Model: Parameter Analyzer B1500A with 1 High Power SMU (HPSMU), 2 Medium Power SMUs (MPSMU), 1 MFCMU and 1 GNU.

Capabilities: I-V measurement (1pA-1A), Pulsed I-V measurement, C-V measurment (frequency up to 1MHz). Windows OS-Based Software. |

|

Laser Writer |

|

|

Super User: Zhang Chi

Model: Microtech Laserwriter LW405-A

Substrate size: up to 150x150 (6”x6”) (mm) Variable resolution: In the Laser Writer system the resolution is changed by replacing the beam focusing optics, which takes only a few seconds |

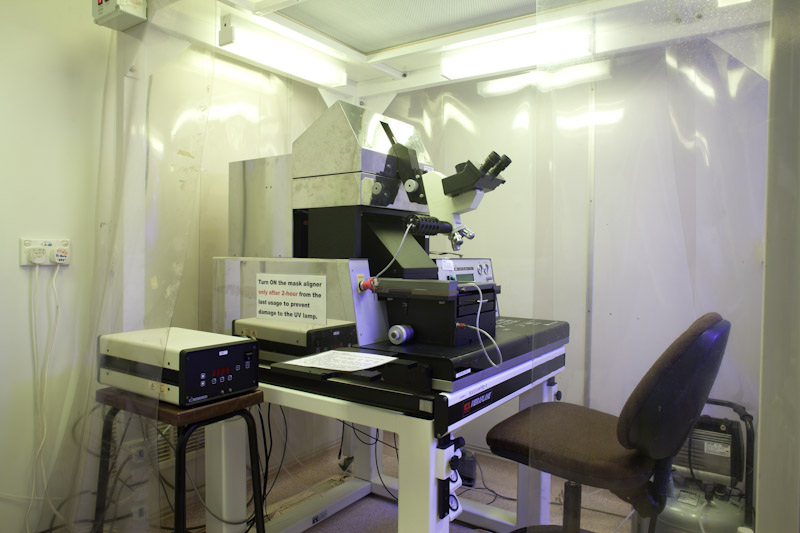

Mask Aligner |

|

|

Super User: Musni

Model: Karl Suss MA6

|

Metal Organic Chemical Vapor Deposition System (AIXTRON) |

|

|

Super User: Chia Ching Kean (IMRE), Terry Zhuo (IMRE), Jin Yunjiang (IMRE)

AIXTRON 200/4 MOCVD system for III-V (Arsenide, Phosphite) material growth research

MO Sources:

Reactor:

|

Metal Organic Chemical Vapor Deposition System (Emcore) |

|

|

Super User: Rayson Tan (IMRE), Soh Chew Beng (IMRE), Zhang Li

EMCORE D-125 MOCVD system for III-V (Nitride) Material growth research

MO Sources:

Reactor:

|

Molecular Beam Epitaxy (MBE) System |

|

Super User: Tung Kar Hoo, Patrick

RIBER 32P MBE system for III-V (Arsenide-based) material growth research

The MBE system can growth III-V semiconductors In(Al or Ga)As(N) Epitaxial Source Materials: In, Ga, Al, and As cracker cell. Doping Materials: Si, Be |

|

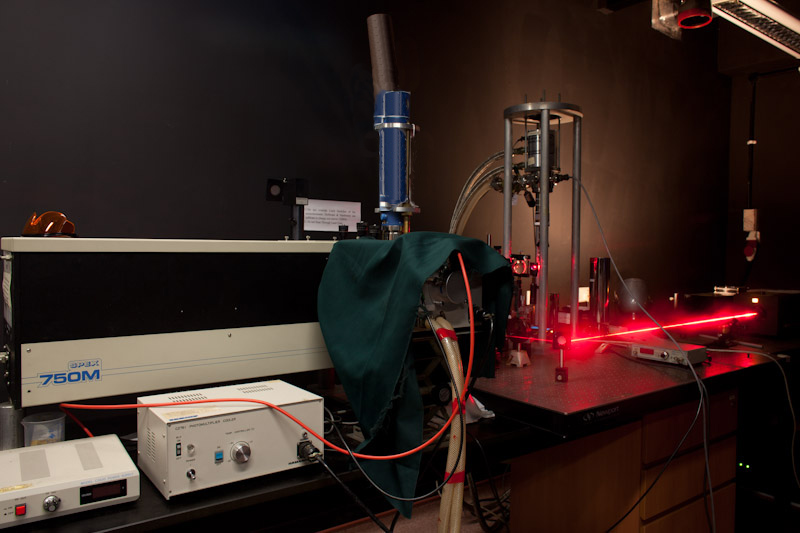

Photoluminescence Optical Characterization (Low-temp) |

|

|

Super User: Musni

Low-temp Photoluminescence setup

Laser Sources:

|

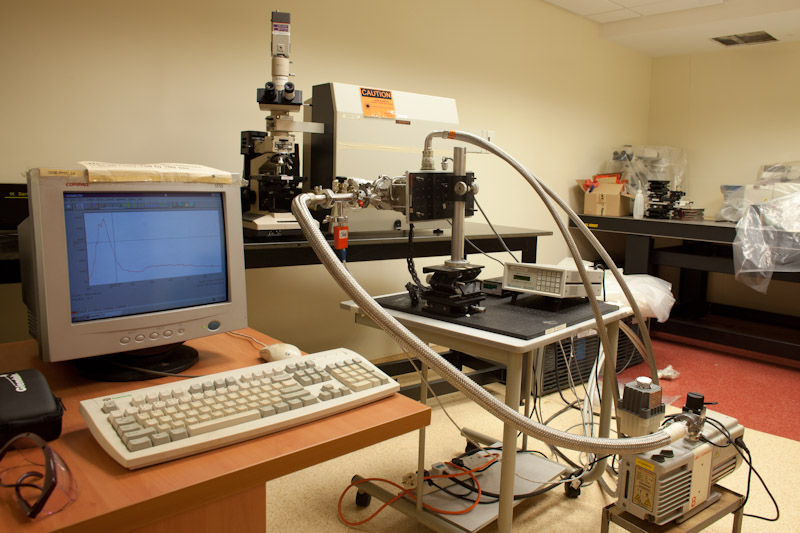

Photoluminescence Optical Characterization (Micro) |

|

|

Super User: Tay Chuan Beng

Micro-Photoluminescence Measurement

Hardware setup based on Renishaw Ramascope 2000

|

Rapid Thermal Annealing System (2 units) |

|

|

Super User: Musni

ULVAC Rapid Thermal Annealing System

Model: Mila-3000

Max size: less than (20 x 20) mm |

Surface Profiler |

|

|

Super User: Musni

Model: Alpha Step 200 (Tencor Instrument, USA)

Vertical sensitivity: Measures the small steps - 20 to 50Å |