DSP based rapid prototyping platform Project

The Project

"DSP based Rapid Prototyping Platform

for

Adaptive Network Controller"

Project Teams

Project Overview

Until recently, PC-based motion control was unpopular in the industry.

This was due to the inherent limitations of the PC bus speed as well as

the lack of floating point computational power required. The

project is to develop a plug-and-play motion control system

(solution oriented) which consists of a DSP based-motion controller card

and all necessary supporting software with a user-friendly GUI based on

PC platform for commercialization.

Project Objects

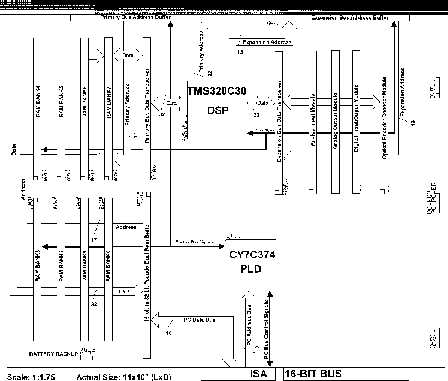

- TMS320C30 is chosen for wire-wrap prototyping

- Smooth transition to a mass product model

offers an easy upgrade path to TMS320C40 and higher performance models

and large shares in the maket.

- 1M <<...>> 32M of RAM is implemented

using zero-wait state static memory with battery backup.

- Two A/D converters multiplexed to give up to 8 channels and six

independent D/A of 16 bit resolution and among others.

Project Technical Issues

- Data acquisation

- System identification

- Control system simulation

- Choices of different control algorithms including PID

neural network, adaptive control or user defined control algorithms

Accomplishments

- Design of a PC-based motion controller card using a DSP for floating

point computations

- Overcome the low ISA bus data transfer rates and other inherent

limitations by performing all motion and servo computations on

the card itself

- The computational core was designed using the TMS320C30, a 32-bit

floating point DSP. This core is supported by 1Mx32 bit zero-wait state

ram, giving up to 4M words of storage

- The design features 4 multiplexable 16 bit A/D channels and 6

latchable 16 bit D/A channels

- Interfacing with industry standard optical encoders, the design also

features 64 digital inputs and 32 digital outputs.

Return to the Home Page

Return to the Home Page